Egg Tray Making Machine

Description

DETAILS

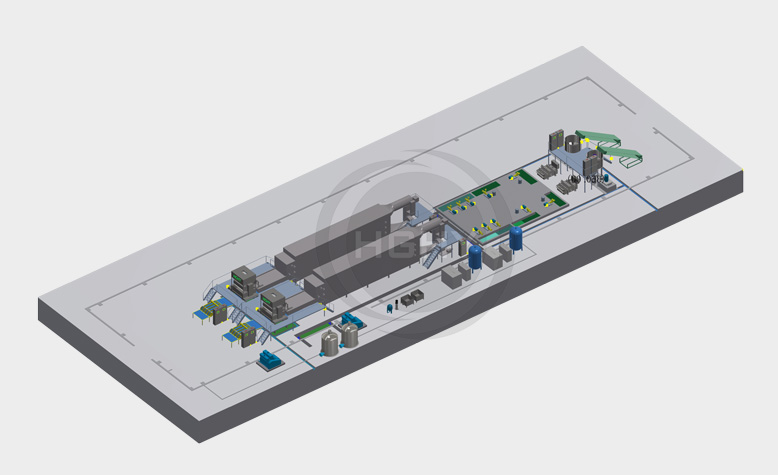

LAYOUT

Description

Feature

High Speed

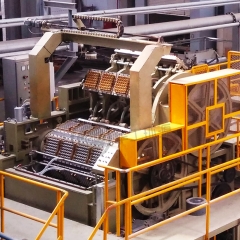

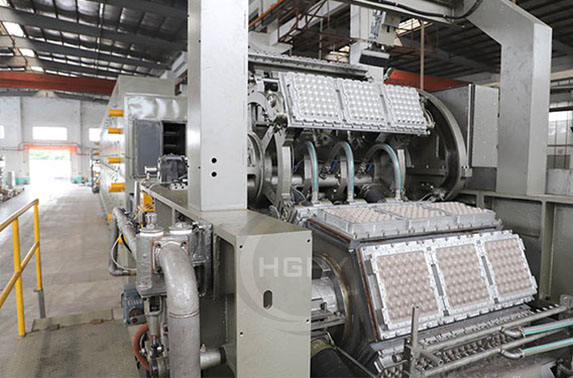

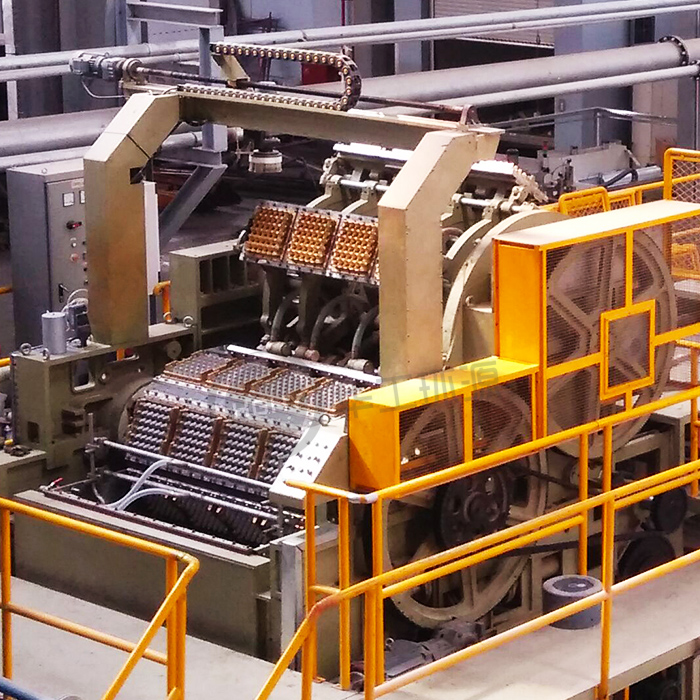

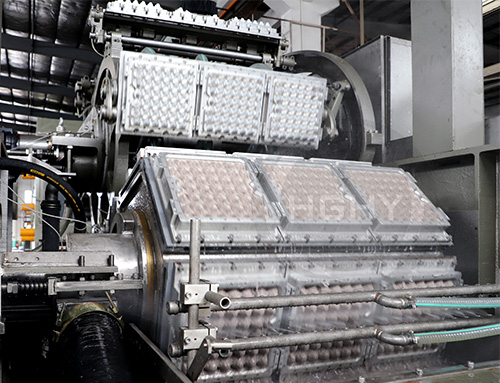

Double Rotary Egg Tray Machine

Double Rotary Egg Tray Machine

Capacity: 7000-12000 pcs / hr

Unique Technology in China, Proven by Running Projects

High speed beyond ordinary, world-class performance.

High Productivity Production Line

Up to 60 Drops per Minute (3 Times Faster)

Platen Size: (1250 or 1650) x 460 mm

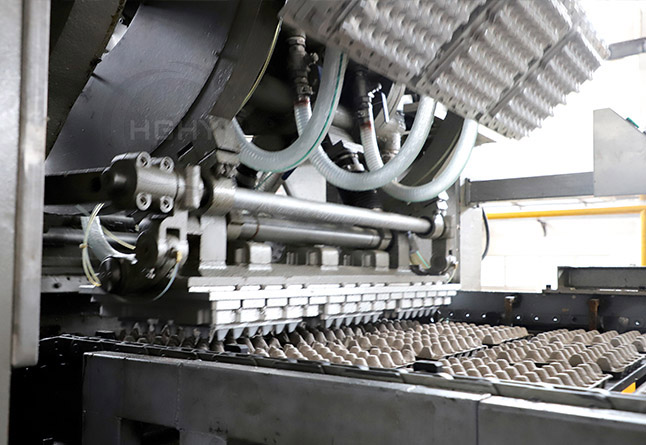

6 Faces Forming 6 Faces Transfer

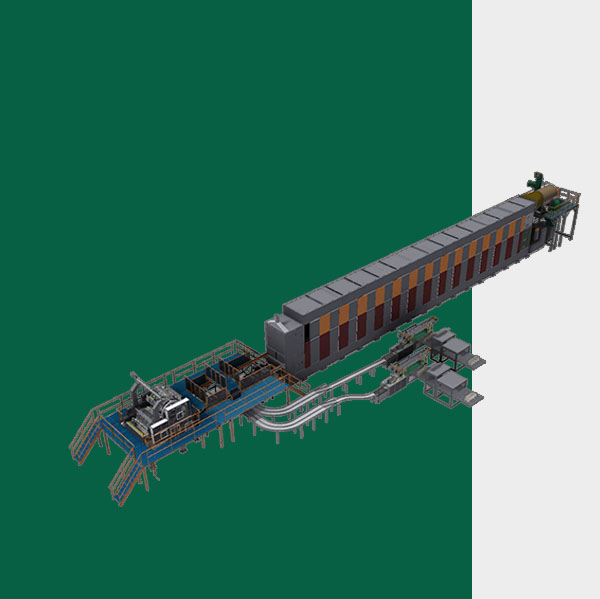

10-Layer Dryer

Greatly Improved Efficiency

Egg Tray Machine Working Video

Have you ever seen a Double Rotary Egg Tray Production Line running? You will see that in the following video. 10 main technical features are worth watching carefully.

Main Features

Pure mechanical synchronous power design;

Large-area maintenance door side by side;

Optimized production wet-to-dry ratio;

Auto cleaning for forming mold and transfer mold;

Heat exchange and recover into hot shower water;

Auto conveying, stacking and counting;

Auto compressing and packing.

Multiple Applications

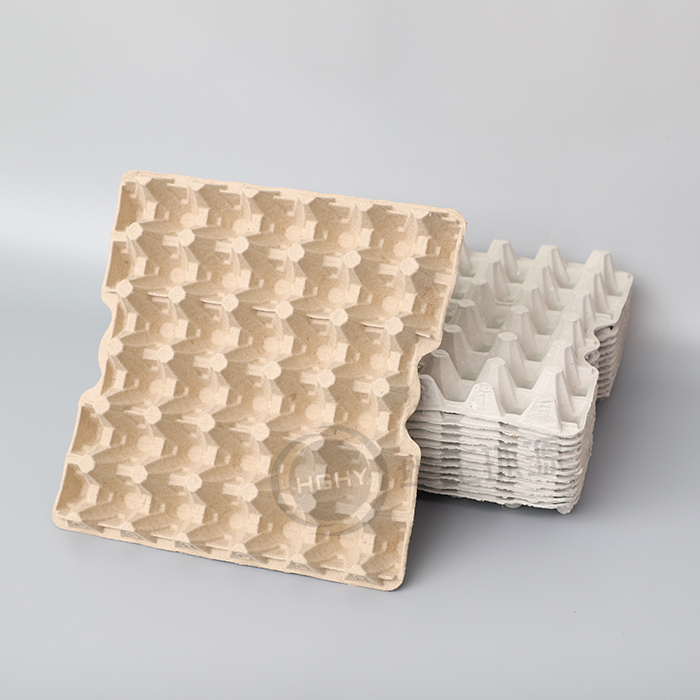

Egg trays

Egg cartons

Coffee cup carrier

Fruit tray like apple trays, berry trays, melon trays, etc.

Keys To Your Success

Stable Operation

High Output

Low Cost

Product quality

Stable Operation

No servo motor, the moulding machine is designed to run synchronously with oven.

Quick and easy access to the oven via large doors;

Safety stop ensuring immediate shut-down for emergency;

PLC process automation, from raw material to end product.

High Output

Up to 20 tons per 24 hours of 30-egg trays. Payback in short term.

Low Cost

Flexibility that helps you reduce energy consumption.

Exhaust heat recovery save energy consumption;

Full automation save man power low as 5 person;

Flexibility of fuels, optional for natural gas, diesel, LPG, industrial oil, etc. whichever is cheaper for you;

Compact design requires less plant area.

Product quality

Constant high level product quality and uniform shape.

Quality and consistency control;

Efficient raw material handling;

Minimize deformation, easy denesting for separation;

Low stacking height, save storage space.

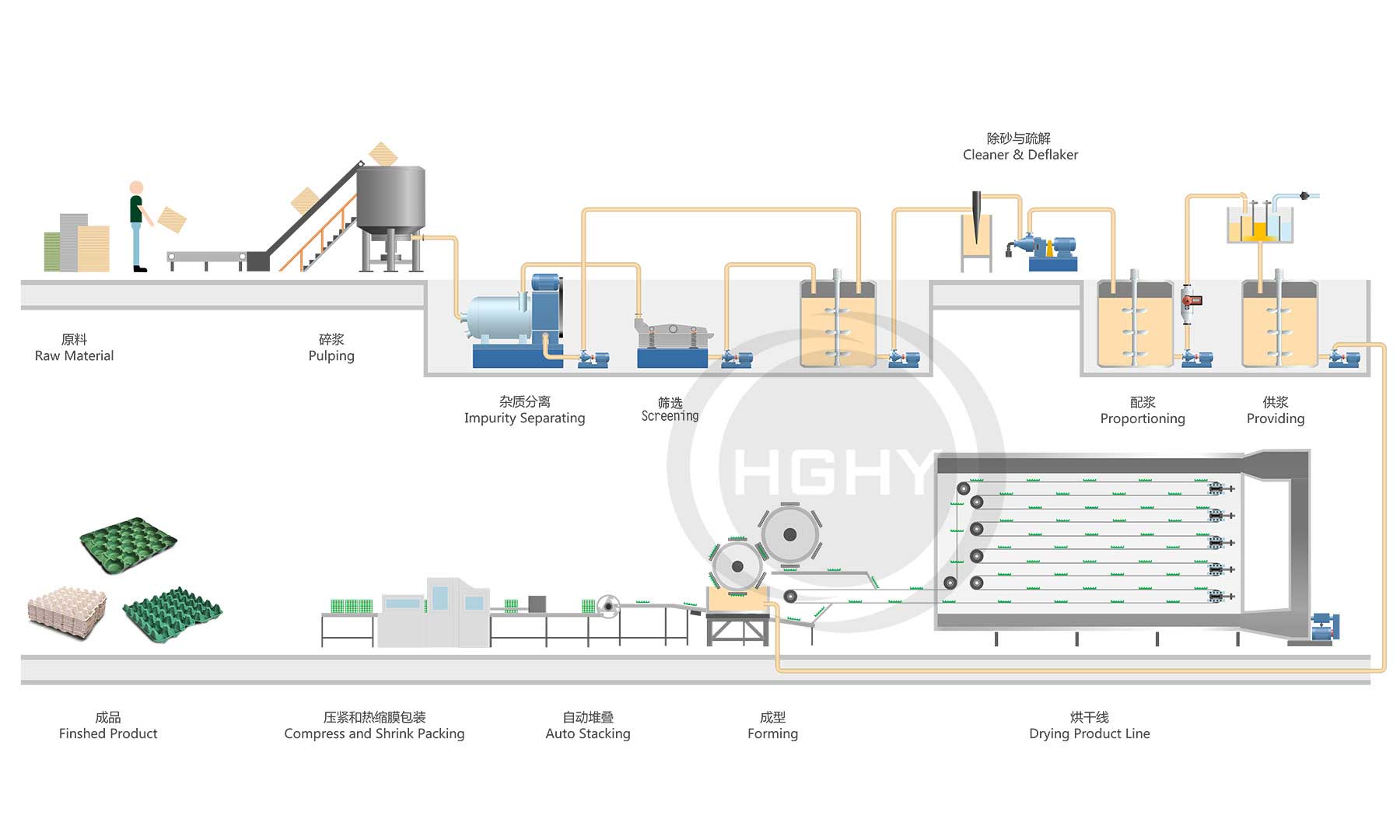

How Molded Fiber Egg Tray is Made

Molded fiber egg tray production line is composed of pulping system, forming system, drying syste, auxiliary system.

Pulp Preparation System

Mainly use waste paper as raw material. The hydrapulper pulp waste paper boxes, waste newspapers, corrugated cardboard and so on. It's impurity separated, screened and deflaker decomposed to form a slurry. Prepare the slurry according to the pulp molding equipment for the next process.

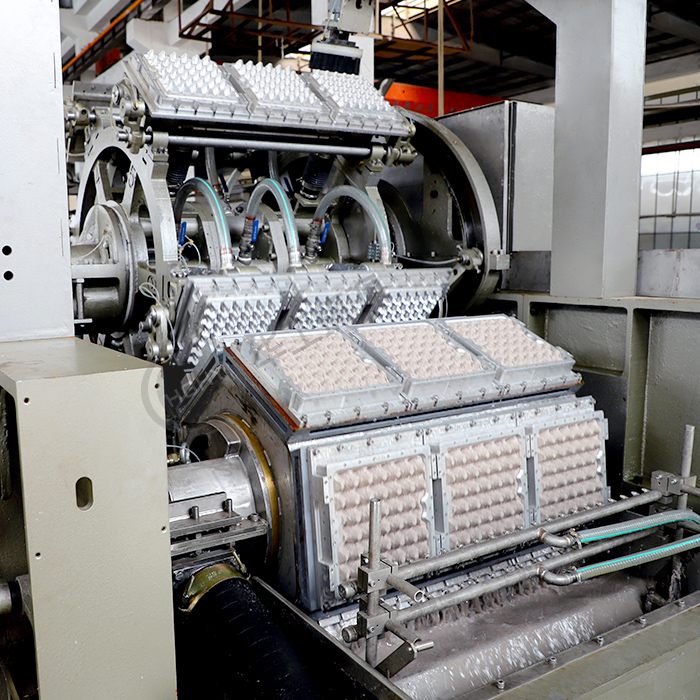

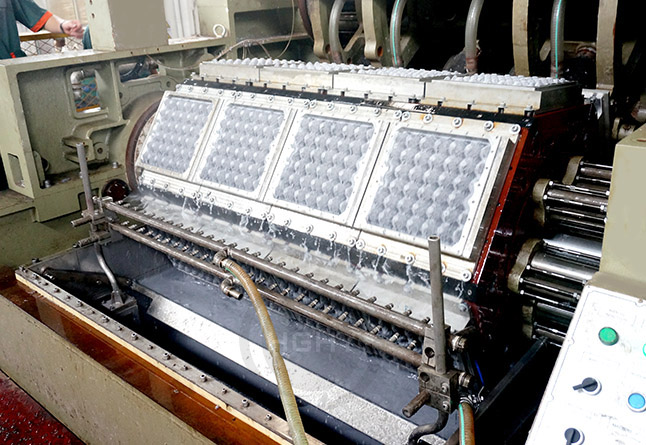

Forming System

The slurry will form product by vacuum suction from the forming mold, then the pulp molding products are transferred by the transfer mold and sent to the next drying line

Drying system

Using enough hot air to blow evenly on the surface of the pulp molding products to remove the water evaporated from the wet products. After drying, it is feeded to auto stacking and shrink packing.

Questions You May Have

How long will it take from order to ship?

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Do you send engineers to installation?

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

Does your machine have a high rate of return? How long will it take to return?

The rate of return is high, and it usually pays back in 2-3 years.

How many countries used your equipment ?

HGHY has helped more than 300 clients in over 50 countries setting up their plants with leading capacity and superior quality production.

DETAILS

Main Specifications

| Model | XZ6.6 -16546 / XZ6.6 -12046 |

| Machine structure |

6 faces forming rotor;

6 faces transfer rotor; With forming mold washing and product flushing;

Including transfer mold auto cleaning device; Preheating hood in the top of forming mold as option. |

| Platen size | 1650x460 mm、1200x460 mm |

| Forming type | Double rotary forming and transfer |

| Cycle time | 1 - 1.2 seconds |

| Mold quantity | 3pcs / 4pcs (based on 30 cabinet egg tray) |

| Maximum product height | 70mm |

| Matching dryer | 10 Layer dryer |

| Control method | PLC + Touch screen |

LAYOUT

Typical Plant Layout