Egg Tray Making Machine

Description

DETAILS

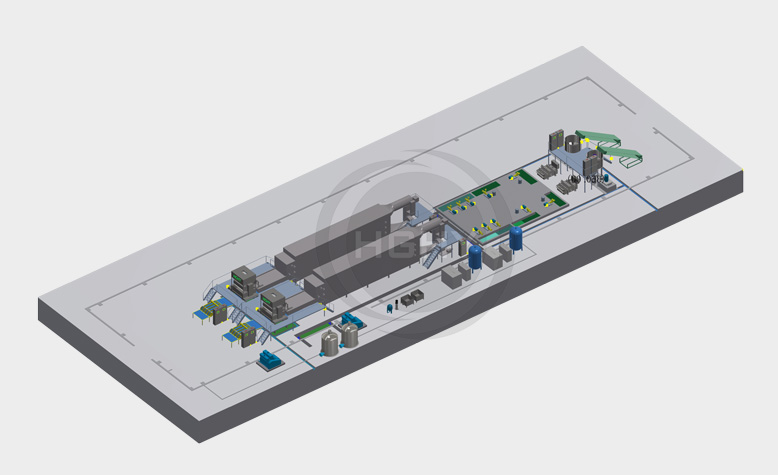

LAYOUT

Description

Feature

Automatic Rotary Egg Tray Machine

Capacity: 2000-6000pcs / hr

Fast Return on Investment

Higher Cost Performance

Higher Cost Performance

Sold out for more than 150 lines

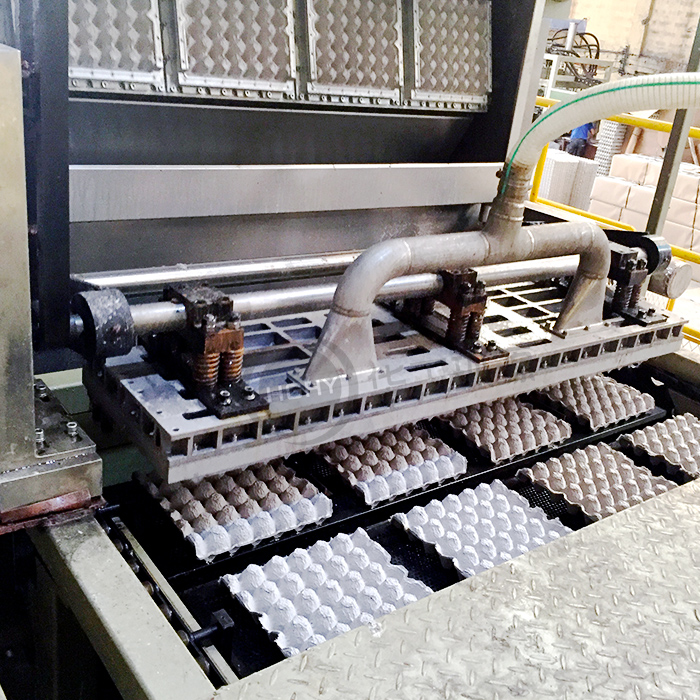

Rotary forming machine

Platen Size: 1600*400MM, 1600*560MM, 1950*420MM, 2350*420MM

6 layer dryer

Egg Tray Machine Working Video

Have you ever seen HGHY rotary egg tray production line runnng video ? Please check it in following video, we can change the mold to produce different kind of products, such as egg carton, furit tray and cup carrier in the real production.

Main Features

Fast investment return, Highly cost effective;

Excellent performance of rotary forming technology;

Match with highly effective 6-pass dryer;

Stronger and less deformed product.

Multiple Applications

Egg trays

Egg cartons

Fruit tray

Drinking cup carrier, etc.

Keys To Your Success

Precious

Reliable

Strong & Durable

Saving cost

Precious

The drum of rotary forming machine is holistic processing.

Material of whole drum is stainless steel;

CNC processing, reduce welding error, higher product quality, more precious in assembly and transfer;

Easier to match forming mold with transfer mold, save time;

Reliable

Pure mechanical power design and more humanize design

Only one motor for forming machine and drying line;

Reliable running and simple opeation;

Less shut down time, less maintenance time;

Wide open door for Drying line.

Strong & Durable

Mold platen made by full piece casting

Better strength;

Longer lifetime;

Good performance.

Saving cost

Utilizing the recycled heat from dryer

Using utilizing the recycled heat for product preheating, reduce the deformation of the final product;

Using utilizing the recycled heat for product preheating for drying line inside using, saving energy;

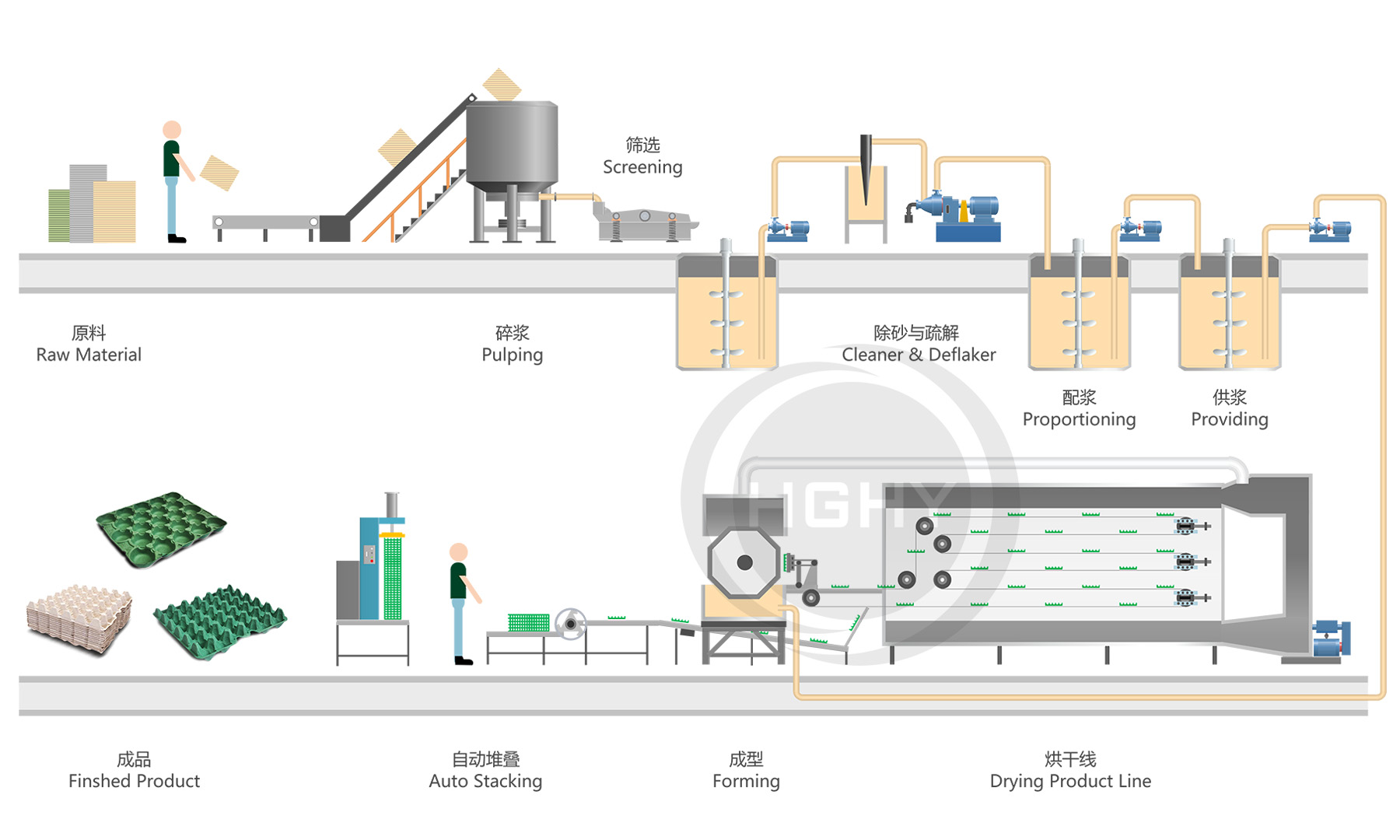

How Molded Fiber Egg Carton is Made

Molded fiber egg carton production line is composed of pulping system, forming system, drying syste, auxiliary system.

Pulp Preparation System

Mainly use waste paper as raw material. The hydrapulper pulp waste paper boxes, waste newspapers, corrugated cardboard and so on. It's impurity separated, screened and deflaker decomposed to form a slurry. Prepare the slurry according to the pulp molding equipment for the next process.

Forming System

The slurry will form product by vacuum suction from the forming mold, then the pulp molding products are transferred by the transfer mold and sent to the next drying line

Drying system

Using enough hot air to blow evenly on the surface of the pulp molding products to remove the water evaporated from the wet products.After drying, it is feeded to auto stacking and shrink packing.

Questions You May Have

How long will it take from order to ship?

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Do you send engineers to installation?

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

Does your machine have a high rate of return? How long will it take to return?

The rate of return is high, and it usually pays back in 2-3 years.

How many countries used your equipment ?

HGHY has helped more than 300 clients in over 50 countries setting up their plants with leading capacity and superior quality production.

DETAILS

Main Specifications

| Model | Optional different model |

| Machine structure |

4faces / 8faces / 12faces, rotary forming;

Transfer the prodcut by 1 swing arm;

With forming mold washing and product flushing;

Preheating system in top of forming machine.

|

| Platen size | 1600x400 mm、1600x560 mm 1950x420 mm、2350x420 mm |

| Forming type | Rotary forming |

| Cycle time | 2.4 - 4 seconds |

| Mold quantity | Each face 3 pcs / 4pcs / 5pcs / 6pcs (based on 30 egg tray) |

| Maximum product height | 70mm |

| Matching dryer | 6 Layer dryer |

| Control method | PLC + Touch screen |

LAYOUT

Typical Plant Layout