The wave of intelligent manufacturing has swept the world with the rapid development of the Internet in recent years. Both Germany, which first proposed industrial revolution 4.0, and United States, which is committed to the development of AI technology, regard intelligent factory as the core of industry 4.0. China as the world's factory come to see its domestic companies following the trend. Traditional manufacturing enterprises including Midea, Gree, Foxconn and Fuyao, as well as non-traditional manufacturing enterprises such as Alibaba group, Jingdong, The Godmother and Zhengda are stepping into the field of intelligent and unmanned transformation.

However, how should traditional pulp molding machine manufacturers maintain strong competitiveness with their products under the current global economic situation? The truth is that there has to keep abreast of times, innovate the product process, and enhance the core competitiveness of enterprises. A great number of enterprises in China are gradually transfer from "Made in China" to "Created in China". It is inevitable for manufacturing enterprises to carry out automation transformation with the proposal of "industry 4.0" and "made in China 2025" strategy.

The pulp molding industry has gone through more than 100 years with advanced technology and rich experience accumulated. However, the development time of pulp molding industry in China is relatively short. Pulp molding industry came to the stage center of the packaging industry owing to the wave of plastic ban in recent years. As the upsurge of replacing plastic with paper is set off globally and the market competition is increasingly fierce, the traditional equipment manufacturing process start to shows its disadvantages.

However, how should traditional pulp molding machine manufacturers maintain strong competitiveness with their products under the current global economic situation? The truth is that there has to keep abreast of times, innovate the product process, and enhance the core competitiveness of enterprises. A great number of enterprises in China are gradually transfer from "Made in China" to "Created in China". It is inevitable for manufacturing enterprises to carry out automation transformation with the proposal of "industry 4.0" and "made in China 2025" strategy.

The pulp molding industry has gone through more than 100 years with advanced technology and rich experience accumulated. However, the development time of pulp molding industry in China is relatively short. Pulp molding industry came to the stage center of the packaging industry owing to the wave of plastic ban in recent years. As the upsurge of replacing plastic with paper is set off globally and the market competition is increasingly fierce, the traditional equipment manufacturing process start to shows its disadvantages.

Then, let's learn about the disadvantages of traditional pulp molding manufacturing process through pulp egg carton making machines.

1. Low capacity is unable to meet huge demand

The nutrition of eggs has met its biggest demand of consumers after being widely popularized. It is reported that the global egg market is expected to grow from US $213.13 billion in 2020 to US $227.39 billion in 2021, with a compound annual growth rate (CAGR) of 6.7%. The growth of egg demand is bound to drive the demand of egg packaging. However, due to the low capacity of traditional egg carton making machines, it is hard to meet the huge market demand of egg packaging.

2. Homogenization of products decrease core competitiveness

As an important part of brand promotion, egg packaging is an important tool to distinguish enterprises from the market. However, the traditional egg carton manufacturing process has greater limitations in product diversity due to the machinery, efficiency, function and other aspects, resulting in serious homogenization of products. The phenomenon can be attributed to that most of the egg carton makers produced by most enterprises are also highly homogeneous, which is not easy for them to stand out in the fierce competition.

3. High production cost

Due to the rough production process, there is a small amount of excessive use of pulp raw materials in the traditional manufacturing process traditional pulp molding machine. It will account for a large share of the total production cost of the enterprise in the long run. At the same time, water and electricity resources will face with the same problem.

Moreover, labor cost has become the main production cost of enterprises with the rapid development of economy. Therefore, In the fierce market competition, enterprises urgently need to lower production cost through automatic production and reducing the allocation cost of production.

Then, let's learn about the disadvantages of traditional pulp molding manufacturing process through pulp egg carton making machines.

1. Low capacity is unable to meet huge demand

The nutrition of eggs has met its biggest demand of consumers after being widely popularized. It is reported that the global egg market is expected to grow from US $213.13 billion in 2020 to US $227.39 billion in 2021, with a compound annual growth rate (CAGR) of 6.7%. The growth of egg demand is bound to drive the demand of egg packaging. However, due to the low capacity of traditional egg carton making machines, it is hard to meet the huge market demand of egg packaging.

2. Homogenization of products decrease core competitiveness

As an important part of brand promotion, egg packaging is an important tool to distinguish enterprises from the market. However, the traditional egg carton manufacturing process has greater limitations in product diversity due to the machinery, efficiency, function and other aspects, resulting in serious homogenization of products. The phenomenon can be attributed to that most of the egg carton makers produced by most enterprises are also highly homogeneous, which is not easy for them to stand out in the fierce competition.

3. High production cost

Due to the rough production process, there is a small amount of excessive use of pulp raw materials in the traditional manufacturing process traditional pulp molding machine. It will account for a large share of the total production cost of the enterprise in the long run. At the same time, water and electricity resources will face with the same problem.

Moreover, labor cost has become the main production cost of enterprises with the rapid development of economy. Therefore, In the fierce market competition, enterprises urgently need to lower production cost through automatic production and reducing the allocation cost of production.

What is the significance of automation transformation for egg carton manufacturing process

According to a market report published by Allied Market Research, the investment in the automation of packaging of eggs and other products might reach $4,649 million globally by the year 2023. This much investment in the automation of packaging indeed indicates that it will be a desperate need in the upcoming days.

In the same way, your plant is not up to date according to the recent demand if you do not have an automated egg carton making machine at your place. There are numerous benefits associated with this machine. Let's take a look at the most important of them.

1. High Production Capacity

An automated egg box machine offers a huge convenience when it comes to scaling up the production of egg trays. With the help of this automatic equipment, the average production of egg trays remains about 50,000 to 60,000, depending upon the capacity of the machine you choose.

2. Reduction in Waste

The waste, which is frequent in the manufacturing of egg trays through manual machines, reduces up to a considerable extent, and a lot of your raw material comes under proper use. The utterly automatic egg box machine is eco-friendly and very easy to operate. The wastewater, as well as waste material through the process, can be reused and recycled.

3. Labor Saving

More labor means spending more money. Yet, you can enjoy more incredible benefits with an automatic egg box making machine. Usually, the typical capacity machine palletizes about four pellets of eggs; 570 eggs in one minute. On the other hand, if you have to reach this capacity manually, you need massive labor at your place.

4. Quality control for products

Unlike humans, automation devices and robots won’t be tired, to say nothing of boredom or loss of interest in work. They even don’t make a lot of mistakes. The accuracy and quality standards of automatic egg carton manufacturing process in more strict than manual system as they eliminates a lot human errors. Pulp egg carton making machines transforming to automation can produce not only higher quality products but also more consistent products.

How Can We Help You?

What is the significance of automation transformation for egg carton manufacturing process

According to a market report published by Allied Market Research, the investment in the automation of packaging of eggs and other products might reach $4,649 million globally by the year 2023. This much investment in the automation of packaging indeed indicates that it will be a desperate need in the upcoming days.

In the same way, your plant is not up to date according to the recent demand if you do not have an automated egg carton making machine at your place. There are numerous benefits associated with this machine. Let's take a look at the most important of them.

1. High Production Capacity

An automated egg box machine offers a huge convenience when it comes to scaling up the production of egg trays. With the help of this automatic equipment, the average production of egg trays remains about 50,000 to 60,000, depending upon the capacity of the machine you choose.

2. Reduction in Waste

The waste, which is frequent in the manufacturing of egg trays through manual machines, reduces up to a considerable extent, and a lot of your raw material comes under proper use. The utterly automatic egg box machine is eco-friendly and very easy to operate. The wastewater, as well as waste material through the process, can be reused and recycled.

3. Labor Saving

More labor means spending more money. Yet, you can enjoy more incredible benefits with an automatic egg box making machine. Usually, the typical capacity machine palletizes about four pellets of eggs; 570 eggs in one minute. On the other hand, if you have to reach this capacity manually, you need massive labor at your place.

4. Quality control for products

Unlike humans, automation devices and robots won’t be tired, to say nothing of boredom or loss of interest in work. They even don’t make a lot of mistakes. The accuracy and quality standards of automatic egg carton manufacturing process in more strict than manual system as they eliminates a lot human errors. Pulp egg carton making machines transforming to automation can produce not only higher quality products but also more consistent products.

How Can We Help You?

Peeping into the realistic scope and benefits of automated egg carton making machine, you would have understood how useful it is for your business. To make it a convenient choice for you, the

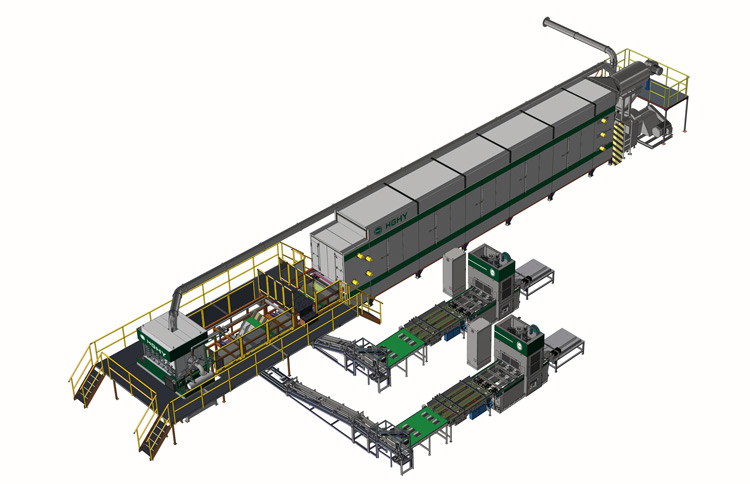

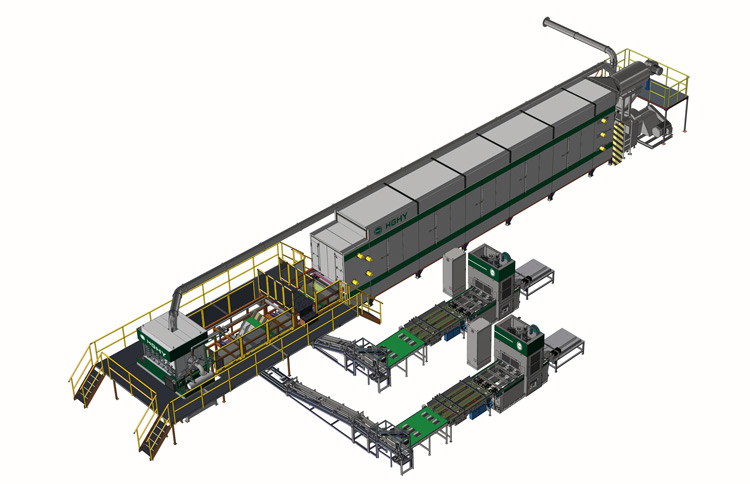

HGHY offers you the best egg carton making machine at a reasonable price. Our automatic in-line hot-press egg carton making machine is efficient and durable, having excellent features that include full automation, the outstanding performance of rotary forming technology, exceptionally productive 6-pass drying line, etc. We also deal in a diversified range of machines that possess the best quality.

Let us know about your interest here.

Request A Quote

Please feel free to give your inquiry in the form below. We will reply in 24 hours.