There are three main solutions to reduce the pollution of waste package in the world: no or less package to use; replace with recyclable packaging; choose biodegrade packaging to prevent harm to the environment if recyclable packaging is not available. The United States, Canada, Japan, the European Union, China and other countries and regions have formulated restriction laws for waste package. ERP materials are prohibited to sale as the transport packaging, replacing with molded pulp products or other easy-to-handle materials.

Pulp molded packaging technology is regarded as a novel technology by comparing with of a variety of raw materials. In addition to meet the needs of various packaging shapes, it is degradable and pollution-free so that it is favored by businesses.

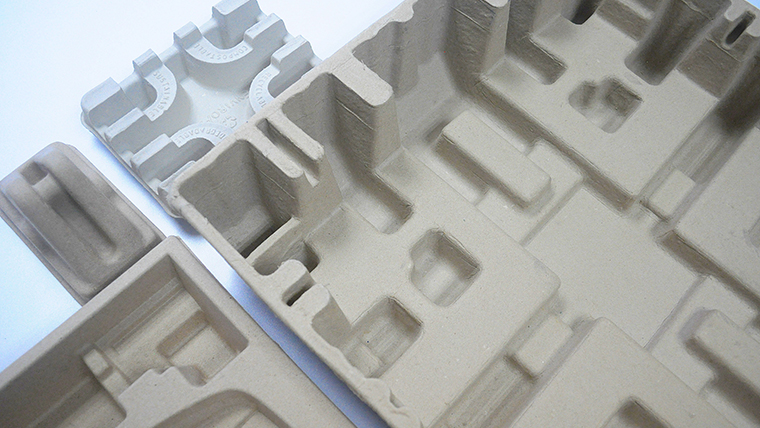

Pulp molding machines are typically considered helpful in producing packaging for poultry and agriculture products. Notwithstanding, the packaging for electronic products is another rapidly emerging opportunity to generate good revenue. Since electronic products are viewed as delicate, electronic packaging is needed to shield the products from severe temperatures, electrostatic discharge, mechanical damage, and high-frequency noise outflow.

Let us now see how pulp molding machines facilitate the electronic industry's packaging:

The Trend in the Future

Due to the ban on plastic use, electronic industries are now finding some other suitable source to get the packaging for their electronic products manufactured. In this scenario, mold pulp packaging gives off an impression of being the best solution because packaging machine manufacturers have included all the mandatory aspects and features into machines to produce packaging for the electronic industry. Apart from this, the benefits associated with using mold pulp packaging have also forced them to come to this conclusion.

According to the report, the electronic packaging market was $1023 million in 2020. This number is expected to touch the figure of $2825.42 million by 2026, with an average increase of 18.5% in the Compound Average Growth Rate (CAGR). All things considered, installing a pulp molding machine for electronic mold pulp packaging will be a money-making business in the coming years.

Mold Pulp Packaging Is Better Than Plastic Packaging

For the packaging of electronic products, mold pulp packaging is in a winning situation compared with plastic packaging. Here are some of the reasons that preferably refer to mold pulp packaging instead of plastic packaging.

1. It is recyclable, reusable, compostable, and biodegradable.

2. Pulp molding machines use 100% recycled materials that reduce the costs of investment.

3. The volatility of prices for paper as a raw material is too low. On the contrary, the prices fluctuate or are usually high when it comes to plastic packaging.

4. It is durable and can withstand harsh weather conditions.

5. Mold pulp packaging offers a cushion for vibration and intense shocks.

6. It saves space and can reduce storage costs by up to 70%.

7. The pulp molding machine offers fully customizable geometry. We can do design engineering according to our requirements.

Environmental Protection and The Organization's Reputation

International Environmental Law (IEL) endeavors to overcome pollution and natural resources' exhaustion with a sustainable development framework. Concerning that, 170 countries have promised to substantially reduce plastics' consumption by 2030, which would help protect the environment.

Essentially, the ban on plastic results from its hazardous nature. On the other hand, the molded pulp for industrial product packaging is 100% safe and environmentally friendly. It is a recyclable material that can get brought into use repeatedly. Subsequently, organizations involved in manufacturing electronic packaging products using molded pulp will be indubitably in the good books of customers and that country's government.

In short, moving your business from plastic to molded pulp can potentially improve your revenues, reputation and brand awareness, and make our environment healthier.

Finally

If plastic packaging products get banned in the coming years, a gap will need to be filled. Along the same lines, mold pulp packaging will be an ideal choice. For this purpose, you must need a durable and versatile pulp molding machine.

Accordingly, HGHY has found a way to meet your electronic packaging needs, as it presents you with its customizable, cost-effective, simple, and flexible pulp molding machine.

Request A Quote

Please feel free to give your inquiry in the form below. We will reply in 24 hours.