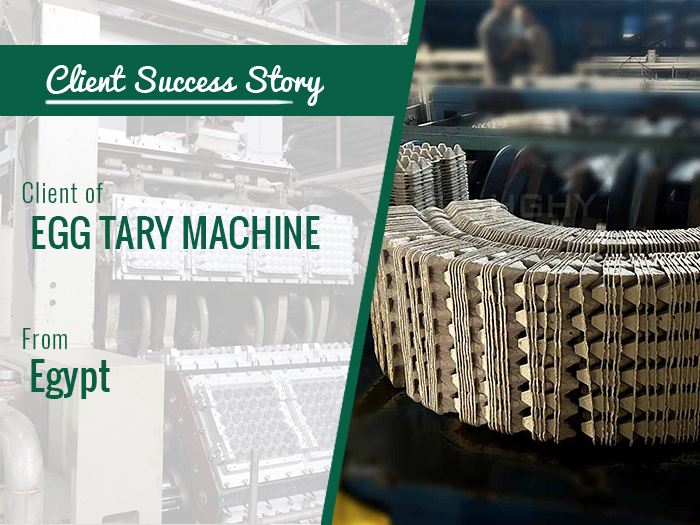

Client Success Story-Egg Tray Machine in Africa

Nov.29.23

A journey of thousands miles to the Middle East --- HGHY always stick to the service of "paying equal attention to products and services" , and insists on giving back to customers with management services throughout the product life cycle.

Client Success Story-Egg Tray Machine in Africa

Nov.19.21

This customer is located in East Africa, it was founded to be the premier manufacturers of Corrugated Carton Packaging materials and Egg trays in East Africa.

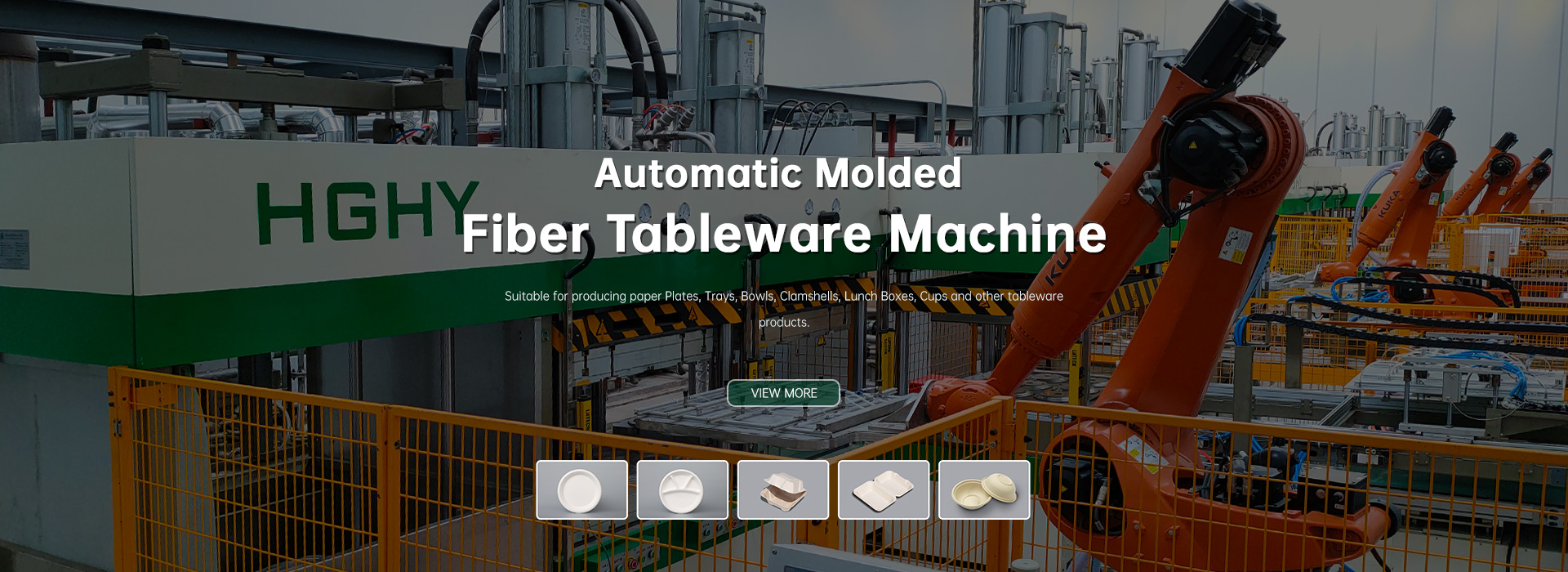

Client Success Story-TABLEWAREMACHINE From Saui Arabia

Jan.28.19

Client Success Story-TABLEWAREMACHINE From Saui Arabia

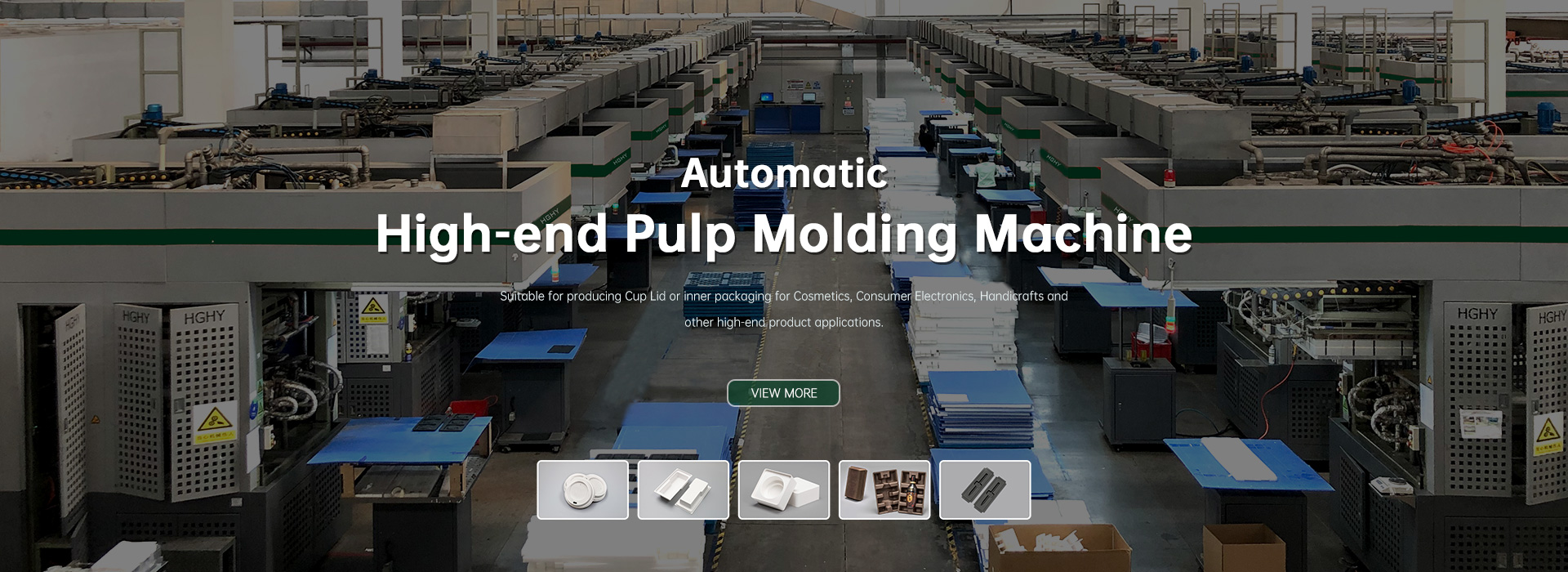

Client Success Story-FRUITTRAYMACHINE From Middle East

Aug.03.21

Client Success Story-FRUITTRAYMACHINE From Middle East

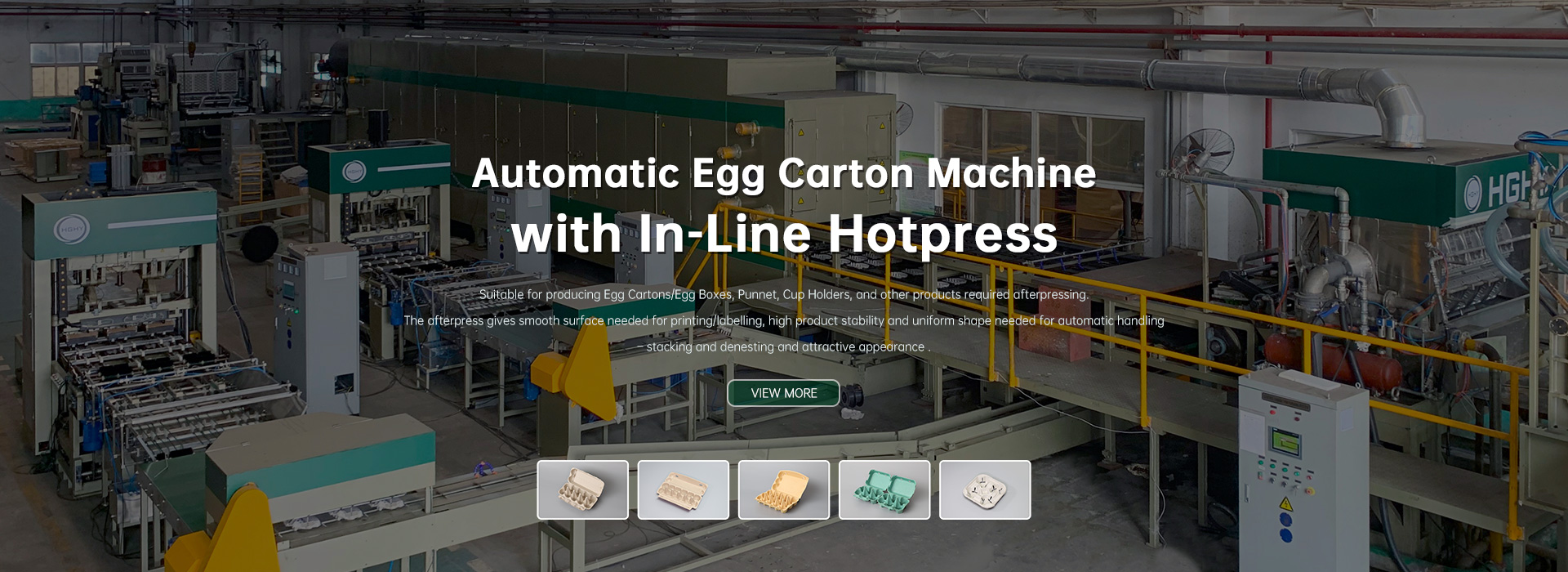

Client Success Story-EGGCARTONMACHINE From Poland

Oct.12.21

Client Success Story-EGGCARTONMACHINE From Poland