Automatic Tableware Machine

Description

DETAILS

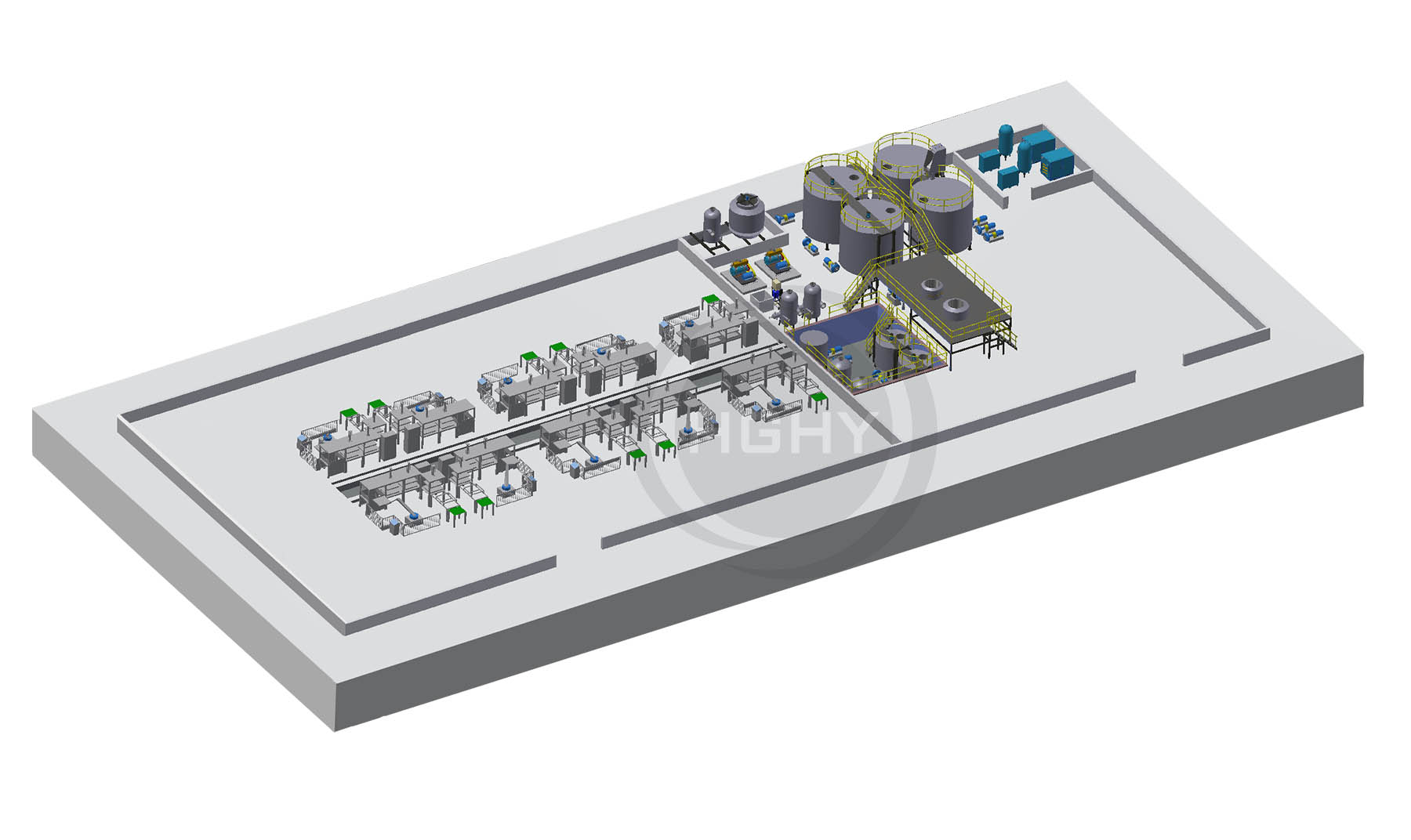

LAYOUT

Description

Feature

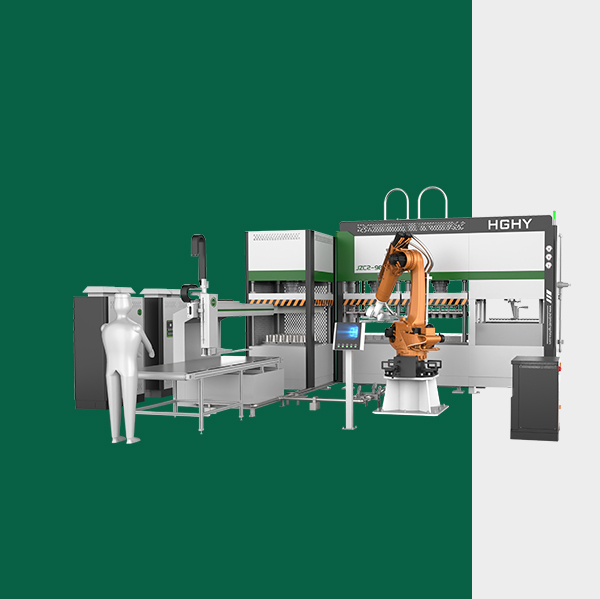

Molded Fiber Tableware Robot System

Daily Capacity: 800KG-1500KG

Simple Or Advanced,

Be Comfortable With Rapid Development

Be Comfortable With Rapid Development

New tech created for new market, has been selling more than 100 units since its launch.

Platen Size: 980 x 940 mm

1 Forming 2 Hotpressing

International Branded Robot Auto Trimming

10 Robots Working Video

Have you ever seen 10 robots working together in 1 plant? You will see that in the following video, and they are making many different disposable tableware items, in the real mass production.

Main Features

High cost performance intelligent control system;

Flexible, accurate and stable production;

Safe and simple operation and maintenance;

Remote intelligent production monitoring;

Trimming and stacking integrated design;

Robots connect the processes intelligently;

Multiple Applications

Disposable Tableware

Paper Plates And Bowls

Fast Food Take-away Box and Lid

Ready Meal Packaging Trays

Supermarket Fresh Trays

Branded Food Packaging

Cup and Lid

Cup Holder and Carriers

Keys To Your Success

Strong & Durable

High Efficient & Automatic

Quality & Energy Saving

Safe & Smooth

Strong & Durable

Three main plates made by full piece casting, no deforming assured for 10 years.

Remote intelligent production monitoring;

Little Giant of Science & Technology in Guangzhou

Trimming and stacking integrated design;

Robots connect the processes intelligently.

High Efficient & Automatic

Full automatic with famous global robot brand.

Resonable layout of machine, easy to change molds;

Open type for easy maintenance;

Special design for uniform forming;

One step hot press and forming.

Quality & Energy Saving

Good design for whole machine to make high quality products.

Adjustable for hotpress air exhaust, no stick mold;

Accurate trimming with good rim;

Special material to reduce heat lose.

Safe & Smooth

Security fence to keep people safe and machine running smooth.

Automatic fault checking and stop itself;

Manage 4-8 machine by one staff;

Stop once inbreak by anything.

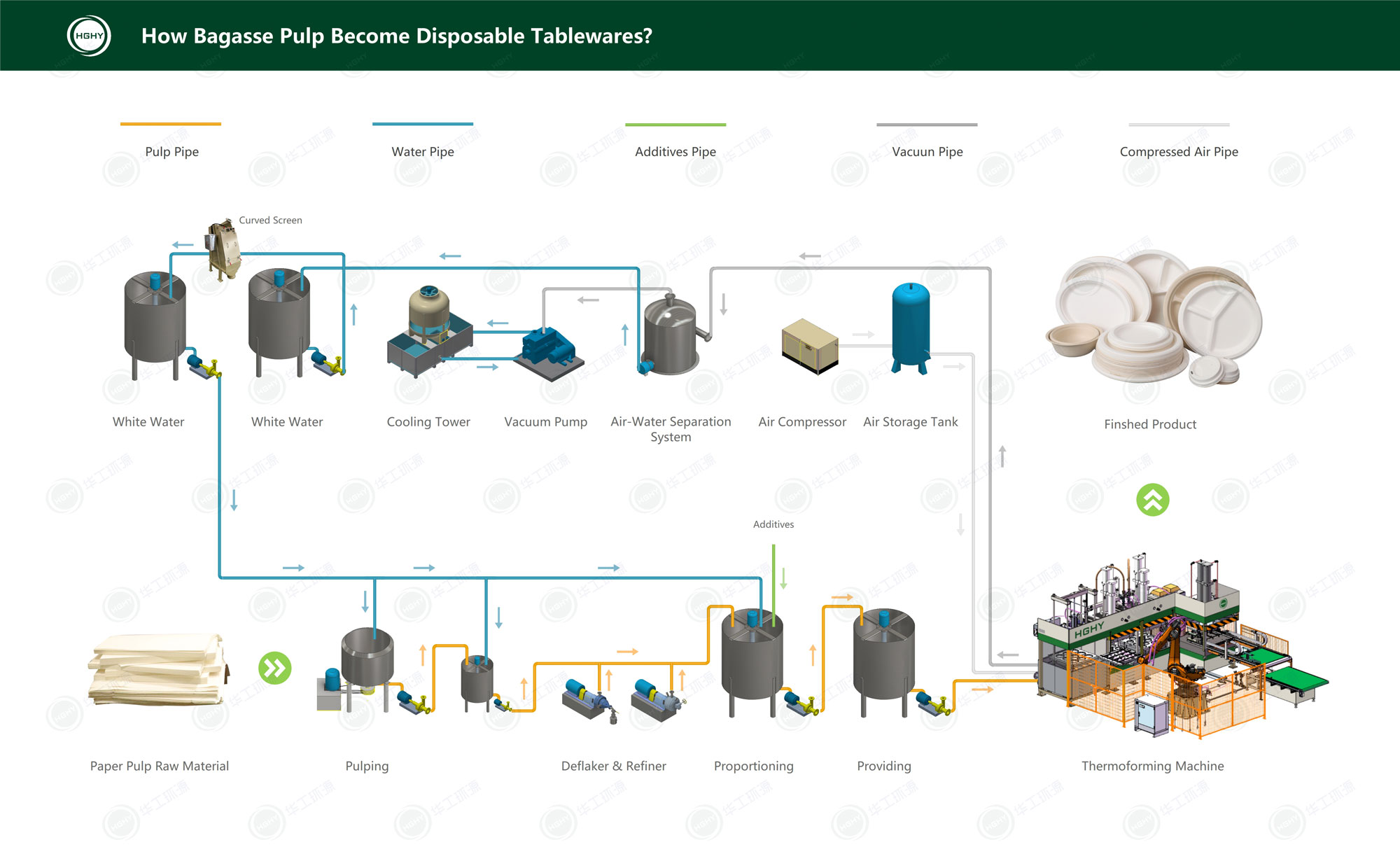

How Molded Fiber Tableware is Made

Molded fiber tableware production line is composed of pulping system, multiple sets of main system (including forming, hotpressing, trimming, stacking and robot), auxiliary system, making pulp molded tableware and food packagings.

Pulp Preparation System

Fiber raw materials after manually weighing, are conveyed into the hydrapulper and mixed with water to form a slurry. The slurry will be pumped to different tanks for the purpose of additive mixing, dilution, cleaning, refining and so on, to become suitable for production of target products.

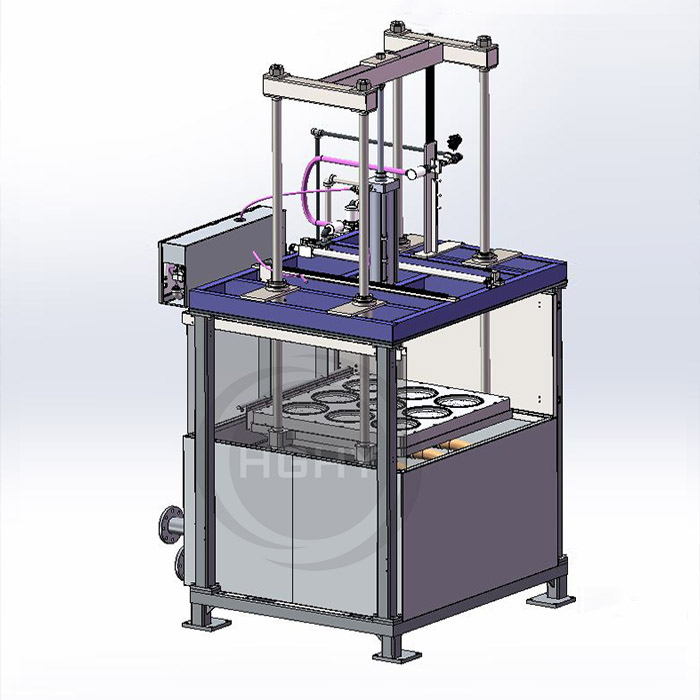

Forming System

The slurry will form a coating on the suction molds by vacuum, then pick up by the robotic arm carrying the upper mold and transfer to the hotpressing stages, at the same time, another robotic arm will pick up dried products from another hotpressing stage to the auto trimming machine.After auto trimming, the finished product will be stacked and counted automatically and ready for final packaging.

Auxiliary System

The vacuum system is utilized to creation suction for the purpose of dehydration for both forming and hotpressing stages, also to fulfill the task of transferring wet and dried products. The compressed air system is to provide pneumatic control and puffing air pressure for products transfer.

Questions You May Have

How long will it take from order to ship?

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Do you send engineers to installation?

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

Does your machine have a high rate of return? How long will it take to return?

The rate of return is high, and it usually pays back in 2-3 years.

How many countries used your equipment ?

HGHY has helped more than 300 clients in over 50 countries setting up their plants with leading capacity and superior quality production.

DETAILS

Main Specifications

| Model | JZW2-9895Q |

| Machine Structure |

1 set of robot;

1 set of forming stage;

1 set of hotpressingstage;

1 set of trimming stage;

Automatic stacking&counting machine

|

| Platen size | 980*940mm |

| Forming method | Reciprocating |

| Heating method | Thermal oil or electrical |

| Hotpressing pressure | Max 25Ton |

| Trimming pressure | Max 60Ton by hydraulic |

| Product height range | ≤ 100mm |

LAYOUT

Typical Plant Layout

Featured Products