Second, the greenness of pulp molded products

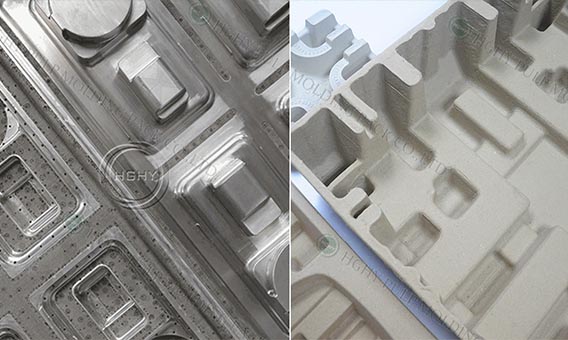

Pulp molded products are made of a certain concentration of pulp (using paper or other natural plant fiber as raw material), adding an appropriate amount of chemical agent, and uniformly making the fibers by vacuum or compression in a model forming machine with a mesh membrane. Distributed on the surface of the mold to form a wet blank with a defined geometry and size, dewatered and stripped, dried and finished to form a paper product with a specific geometric cavity structure and a certain pressure-resistant buffering capacity.

Through the above pulp molding technology, the pulp raw material can produce different specific paper products under the use of different film materials, the product has rich geometric shape and good anti-shock, anti-shock, anti-static and the like, and has a wide source of raw materials. The products are light in weight, high in compressive strength, stackable, and low in storage capacity, and are widely used in the packaging of products in various fields. The lightest material withstands the heavy weight, not only has good cushioning and shockproof performance, but also is an environmentally friendly material that can be recycled, which fully reflects the greenness of pulp molded products and raw materials.

Third, the green process and recycling channels of pulp molding

The process of producing pulp molding is to convert the waste paper into a pulp by a water pulper, and then transfer or remove the film by vacuum adsorption or grouting on a special-shaped mold (a mold similar in shape to the package). Drying and other processes, some products need to be properly shaped. In the whole process of production, most of them are physical processes. Even if some reinforcing agents and water repellents need to be added, there is no influence on the health and environment of producers and users. Part of the water used in the production process is evaporated by evaporation, and the other part is recycled. Therefore, the production process of pulp molding is also “green”.

After the pulp molded products are discarded, the processing method is flexible. It can be roughly divided into three methods: one recycling and recycling paper or continuing to make pulp molded products; two natural degradation, turning into fertilizer to increase soil organic matter; and three for incineration in the case of urgent need for treatment, without generating toxic gases. Therefore, pulp molded waste is also “green” and environmentally friendly.

Therefore, pulp molding forms a perfect green closed loop from raw materials, production and waste disposal, which not only saves natural resources and protects the ecological environment, but also highly conforms to the development trend of the application of materials in the international packaging industry, thus becoming plastic tableware and packaging The best substitute for products. product. Pulp molded products have huge social and economic benefits and are ideal green packaging products in the future.