Industrial Packaging Machine

Description

DETAILS

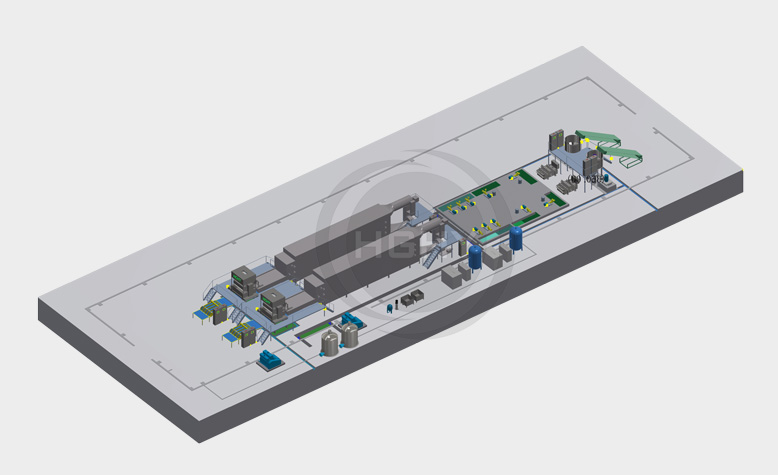

LAYOUT

Description

Feature

Molded Pulp Packing Machine

Capacity: 1200 pcs/hr

All kinds of platen sizes could be customized upon demand

High efficient and lower consumption drying line

Flexible configuration options;

Various platen sizes for diversified products Reciprocating forming more stable;

High efficient and lower consumption drying line;

Long-term experience in cooperating European customers.

Molded Pulp Packing Machine Working Video

High efficient and lower consumption drying line and Real customer case You will see that in the following video.

Main Features

Simple and flexible operation and maintenance;

Lower cost of matching with molds;

Optional with semi auto type and fully auto type;

High efficient and lower consumption drying.

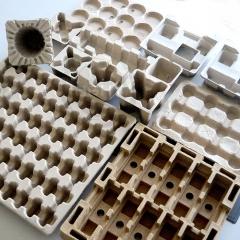

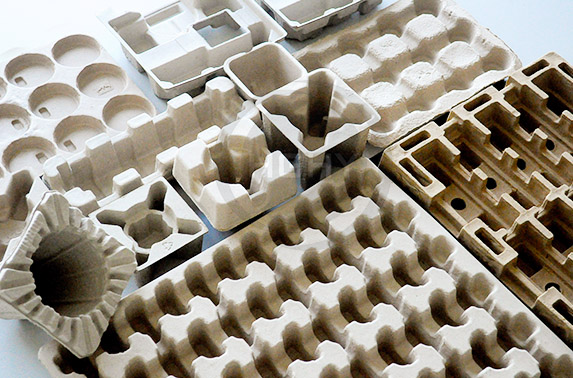

Multiple Applications

Electronic packing

Tools packing

Accessories packing

Household appliances packing, etc.

Keys To Your Success

Flexible Configuration

Long services time

Low Consumption

Various Products

Flexible Configuration

Forming time shortly;

Single station and double station options;

Different sizes of plates would be customized on demand;

Mold height up to 130mm.

Long Services Time

Up to 15 years of experience in cooperating with European and American customers.

Low Consumption

Energy-efficient drying line.

Adjustable air outlet;

Directional drying accuracy;

Efficient frequency conversion control;

Up to 35% saving space.

Various Products

Household appliances packaging;

Electronic packaging

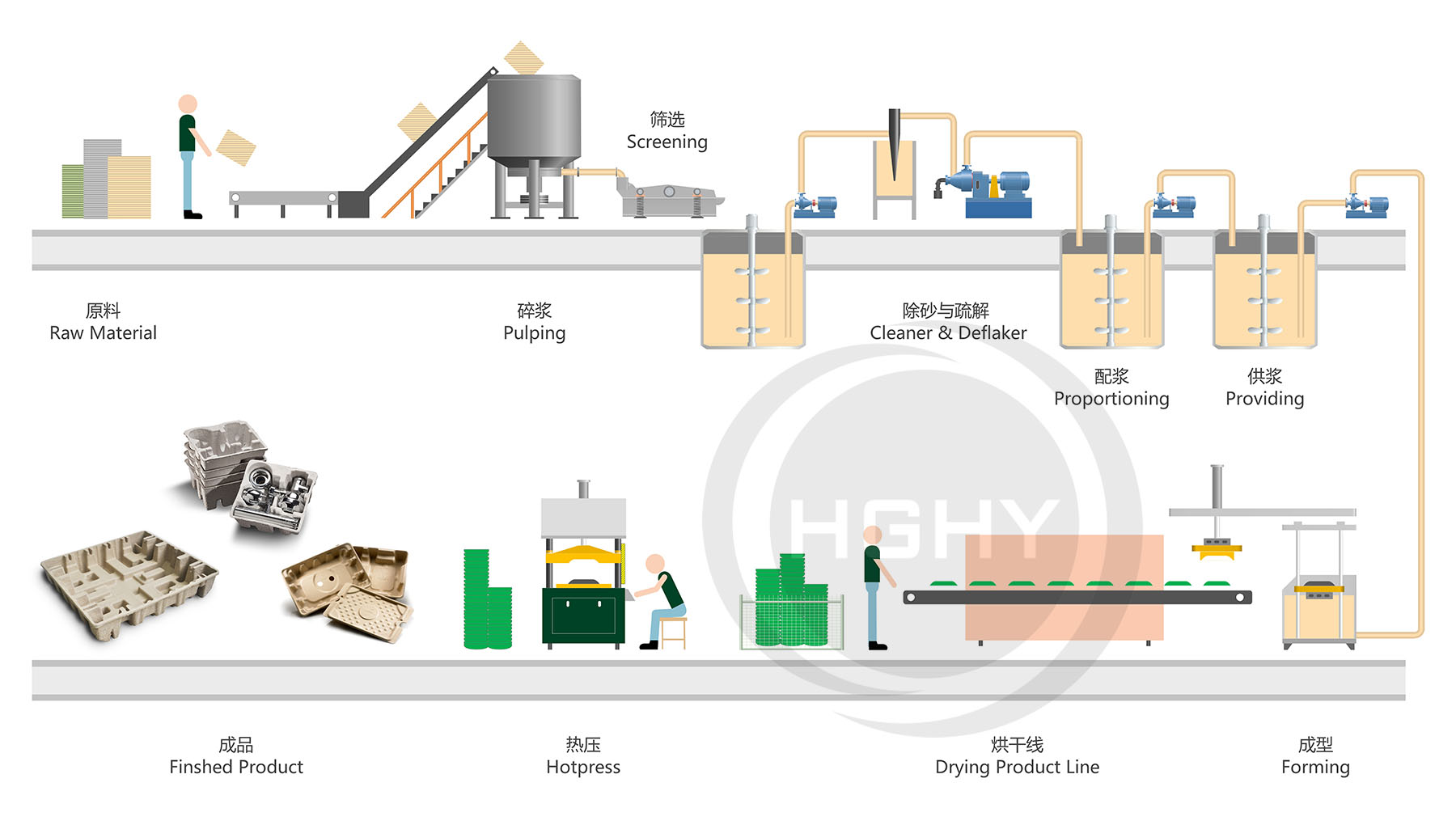

How Molded Fiber Industrial Packing is Made

Molded fiber industrial packing production line is composed of pulping system, forming system, drying syste, auxiliary system.

Pulp Preparation System

Located in the Science City, east of Guangzhou, about 1 hour drive from BaiyunInternational Airport. Servicing for project design, chief engineering, after-sales service, sales and marketing, financial, human resource and top managements.

Forming System

Located in the DatangIndustrial Park of Foshan, about 1 hour drive from BaiyunInternational Airport. Servicing for in-house machinery design and R&D, manufacturing,assembly, quality management, test-run, installation start-ups, engineering and commissioning.

Auxiliary System

Located in the DawangNational High&NewTech Zone of Zhaoqing, about 1.5 hour drive from BaiyunInternational Airport. Servicing for in-house technology R&D, mold design and manufacturing. A New Complex is under construction in the nearby area.

Questions You May Have

How long will it take from order to ship?

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Do you send engineers to installation?

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

Does your machine have a high rate of return? How long will it take to return?

The rate of return is high, and it usually pays back in 2-3 years.

How many countries used your equipment ?

HGHY has helped more than 300 clients in over 50 countries setting up their plants with leading capacity and superior quality production.

DETAILS

Main Specifications

| Model | Optional different model |

| Machine structure |

Forming upper platen x 1;

Forming lower platen x 1; Upper platen move out to the reciving table automatically; Match with dryer by auto feeding automatically. |

| Platen size | Various specification are available |

| Forming type | Reciprocating forming and turn over forming |

| Cycle time | 15 - 60 seconds ( adjustable based on different product) |

| Matching dryer | Drying line or drying tunnel or single layer dryer as optional |

| Control method | PLC + Touch screen |

LAYOUT

Typical Plant Layout