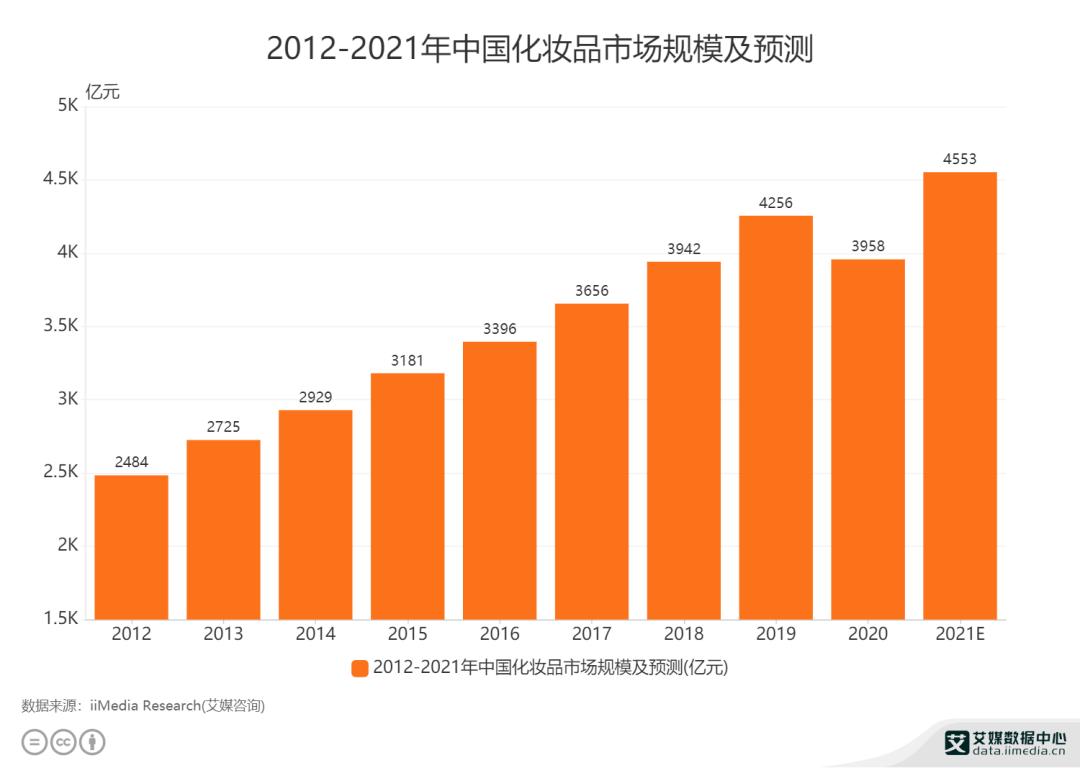

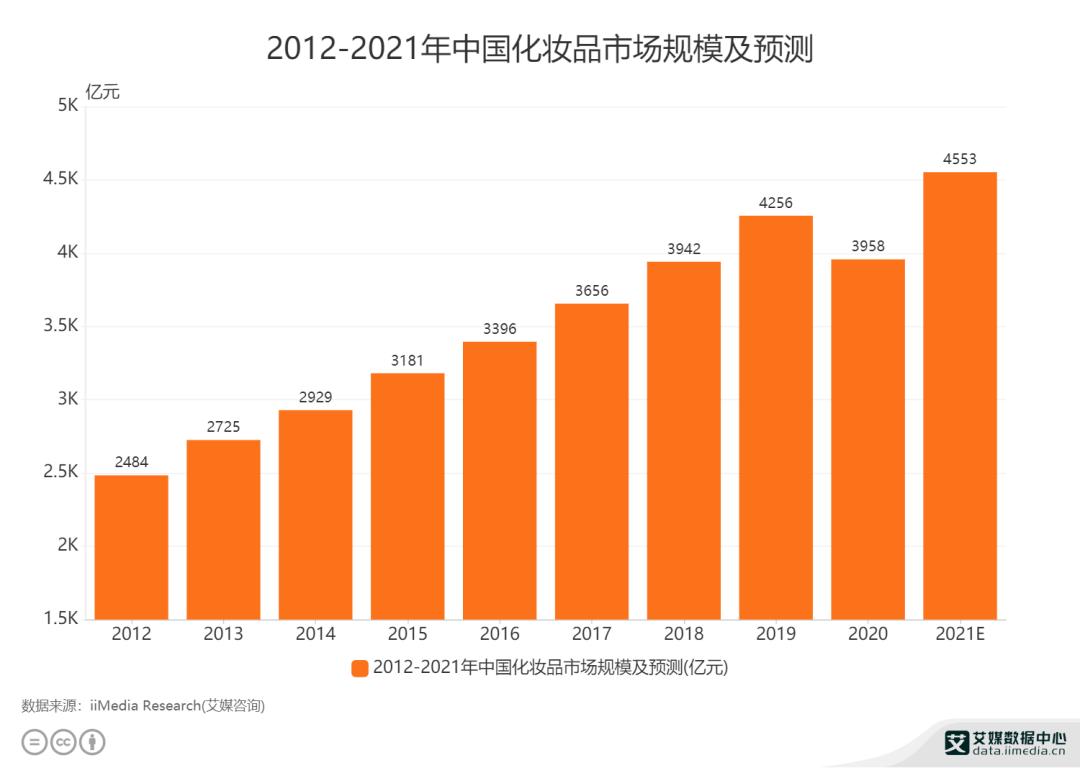

With China's GDP per capita surpassing $10,000 for the second year in a row, the world's largest single middle class market was created, a market that has never existed in human history. This market will continue to produce miracles. As the new crown epidemic gradually comes under control, the consumer goods market will produce even more miracles. Consumers in this context are demanding higher and higher quality of life.

The cosmetic industry, standing at the forefront of the market, can sense more changes from consumers, and this area, too, is one of the markets where plant fiber molded packaging is making the fastest progress.

Today we share with our friends a large number of cosmetic plant fiber molded packaging.

The most emphasis on the quality of beauty and skin care products are also receiving more and more attention from users, hoping to buy more "good" products. If you look at the packaging alone, without considering the quality, I believe that most consumers will pay for it. This is because cosmetics need quality pulp molding packaging design to enhance their value.

In fact, cosmetic packaging is the fastest growing segment of sustainable packaging in the entire packaging sector. Cosmetic packaging should be protective, functional, decorative and luxurious, bringing consumers a more efficient and pleasant sense of visual enjoyment, satisfying their psychological, spiritual and cultural needs, and giving full play to the significance of the cultural value and brand value of cosmetic pulp molding packaging.

RUKA Wig brands

Founded in 1960, Redken was acquired by L'Oréal in 1993 and became a professional salon hair care brand under L'Oréal. The brand also introduced the "Redken Golden Triangle" theory, which means that each product line combines Fashion, Science and Inspiration. L'Oréal launched a paper bottle for REDKEN, which was hailed as the first shower-safe paper bottle produced in the beauty industry.

JamesCropper is a major player in the luxury packaging industry, and their serial pulp molded products are truly appreciated.

The US-based hair product rahua has launched its first ever refill packs, including the popular classic Miracle Kernel Shampoo refill pack and the Miracle Kernel Shine Hair Lotion refill pack. The packaging is made from 60% decomposable plant fibers, reducing the use of plastic by 90%, which not only extends the life of the original empty bottle, but also reduces the carbon footprint of shipping.

nicknack

To talk about one of the hottest green eyeshadows recently, it is important to mention a brand nicknack nekona, the choice of plant fiber molded packaging.

As a brand that cares about product safety and environmental sustainability, nicknack also creates a new "makeup ecology" for all the fairies. Who says beauty and environmental protection have nothing to do with each other, as the new human beings, you can also protect the earth while being beautiful. This is not also the most "fashionable" way of life nowadays.

nicknack shell packaging is extracted from sugarcane bagasse, is completely biodegradable paper environmental protection packaging, does not sound super cool it?

BIOHYALUX

As a socially responsible medical skincare brand, recycles bagasse into its product pulp molding packaging. Sugarcane bagasse is made into round inner packaging using extraction and semi-automatic wet pressing technology, which is reasonably placed and easy to carry.

In addition to the high compatibility of the product concept and packaging materials, we extracted [30] [60] from the product characteristics of "30-day skin improvement process, 60-day food-grade shelf life" and cleverly integrated the use of 1, 2, and 3 stages into the visual identity using a numerical structure. The production process was successful in overcoming the problem of extracting impurities from bagasse and stamping a screen on the outer packaging arc wall.

Above & Beyond

Moving away from a world of single-use plastics, Above & Beyond created a sustainably driven packaging system for Sulapac. The pulp molding packaging is made from wood and plant-based binders from industrial sidestreams, making it compostable and biodegradable. In addition, the lip balm is made from an infinitely usable aluminum case, creating a beautifully sustainable packaging system.

United & Free

We partnered with United & Free to create a hair and skin care line that eliminates the amount of packaging in the bathroom by creating a multifunctional product that offers three solutions. For every 10 tons of sugar cane crushed, a sugar mill generates nearly 3 tons of bagasse waste. Made from the waste stream, we created a casing to protect United & Free's balsam on the shelf and in transit. The custom form of the outer packaging outlines the curvature of the bottle, a metaphor for the transparency that is the foundation of United & Free's values. The bagasse pulp molding packaging is ready to compost once opened, closing the loop.

Chanel

French luxury brand Chanel has won an award for sustainable packaging at the Formes de luxury Awards, the luxury packaging awards that have honored the industry's best innovations each year for more than 20 years. The winning entry was a collaboration between Chanel and the American design firm Knoll, using 100% Knoll Ecoform pulp flip-top packaging to mark the 100th anniversary of Chanel's iconic No. 5 fragrance. The flip-top-shaped outer packaging (below) is made from FSC-certified bamboo and bagasse (waste from sugar cane), which is biodegradable and recyclable.

Chanel designs eco-friendly pulp packaging that is unprecedented in the luxury packaging industry. This project redefines the benchmark for sustainable luxury packaging. As we continue to push the entire industry towards new standards of sustainable packaging, it is expected that our clients will follow in these footsteps."

The project comes on the heels of Chanel's creation of the first bottle for No. 5 using recycled glass, designed and manufactured by Chanel in collaboration with French cosmetics pulp molding packaging production giant Groupe Pochet, the first time Chanel has used recycled glass for a perfume bottle.

Mosh

Mosh is more than just a health brand; the brand's packaging, designed by Think Packaging, helps shift the product from prescription to self-care. The simple design, focused on printed descriptions, feels easy to understand while maintaining a good sense of familiarity.

Mosh re-partnered with Universal Favorite to focus on conveying the personality inherent in the Mosh brand - approachable, Australian and optimistic. The use of the logo was limited by the logo and the task of communicating the brand and personality through clever packaging design. SolutionsWe defined the direction of the product design, looking for different shapes and styles with flexibility across multiple product verticals.

Here's a cosmetic product that can be refilled directly.

Consumers who habitually use the same brand of cosmetics can easily save up a large pile of identical plastic packaging. Since cosmetic containers are generally small in size, consumers can't think of a good way to use them twice, even if they are inclined to do so. So a sustainable packaging solution was offered: refillable boxes.

These refillable boxes can cover a variety of product types such as eye shadow, mascara, lipstick, foundation, etc. They can be easily disassembled and reassembled, so that when consumers use up a cosmetic product and buy it back, they no longer need to buy the product with a new box, but can simply buy the "core" of the cosmetic product at a cheaper price and put it in the original box itself. Instead of buying the product with a new case, you can buy the "core" at a cheaper price and put it in the original case. In addition, in addition to the traditional metal case, the company has designed a special case made of biodegradable, compostable paper, which can be filled again and again without worrying about contamination when throwing it away.

Fedrigoni Paper Snap

Beauty product samples become more sustainable with the Fedrigoni Paper Snap®, a single-dose packaging option made of paper that replaces any existing single-dose plastic packaging in a more sustainable way, not only does it not waste a drop of product, but it is fully recyclable.

Easily opened by folding it in half with one hand, it's perfect for brands to distribute at events, in crowded stores or anywhere busy.

Estée Lauder

Estée Lauder announced that it has joined the partnership alliance with sustainable packaging technology company Pulpex, becoming the first premium beauty company within the alliance. Estée Lauder Group will help promote the upgrade of Pulpex's pioneering paper bottle technology to advance sustainable packaging solutions for the beauty industry.

The paper bottle technology developed by Pulpex uses wood pulp to make bottles from renewable wood pulp sourced from responsibly managed forests, a raw material that is FSC (Forest Stewardship Council) certified. The paper bottles thus produced can be widely recycled in the standard waste disposal process. The use of Pulpex paper bottles will help Estée Lauder Group reduce the environmental impact of its products during their life cycle due to packaging.

The goal of the Pulpex Partner Alliance is to help the Pulpex paper bottle scale up quickly and be widely used in many different product categories. Going forward, the Estée Lauder Group will promote the use of Pulpex bottle technology across its portfolio of brands, an initiative that will advance Estée Lauder's global sustainable packaging goals.

ESCAPE

The design of this cosmetic packaging, which is molded in pulp to meet consumer demand for environmentally friendly products, won the favor of the IF Award jury.

The envelope of the packaging is in the form of a supermarket bill, and the "skin bill" expresses the product's ability to provide a comprehensive solution to skin problems, suggesting the creation of the perfect makeup.

The outer box is a pulp molded egg carton, which not only adds fun and authenticity, but also borrows the common egg carton to increase the friendliness and life style of the product, catering to the new generation of consumers, as well as promoting the significance of environmentally friendly packaging materials.