In recent years, with the implementation of the upgraded "Plastic Ban", the establishment of the "double carbon" goal, and the continuous strengthening of consumers' awareness of environmental protection, the demand for green packaging in many industries has continued to grow. A new alternative to pulp molded products have quietly become popular.

Moreover, with the continuous progress of intelligent equipment technology, the pulp molding process has made rapid progress, and the birth of a large number of application scenarios has triggered a boom in the paper and plastic manufacturing industry.

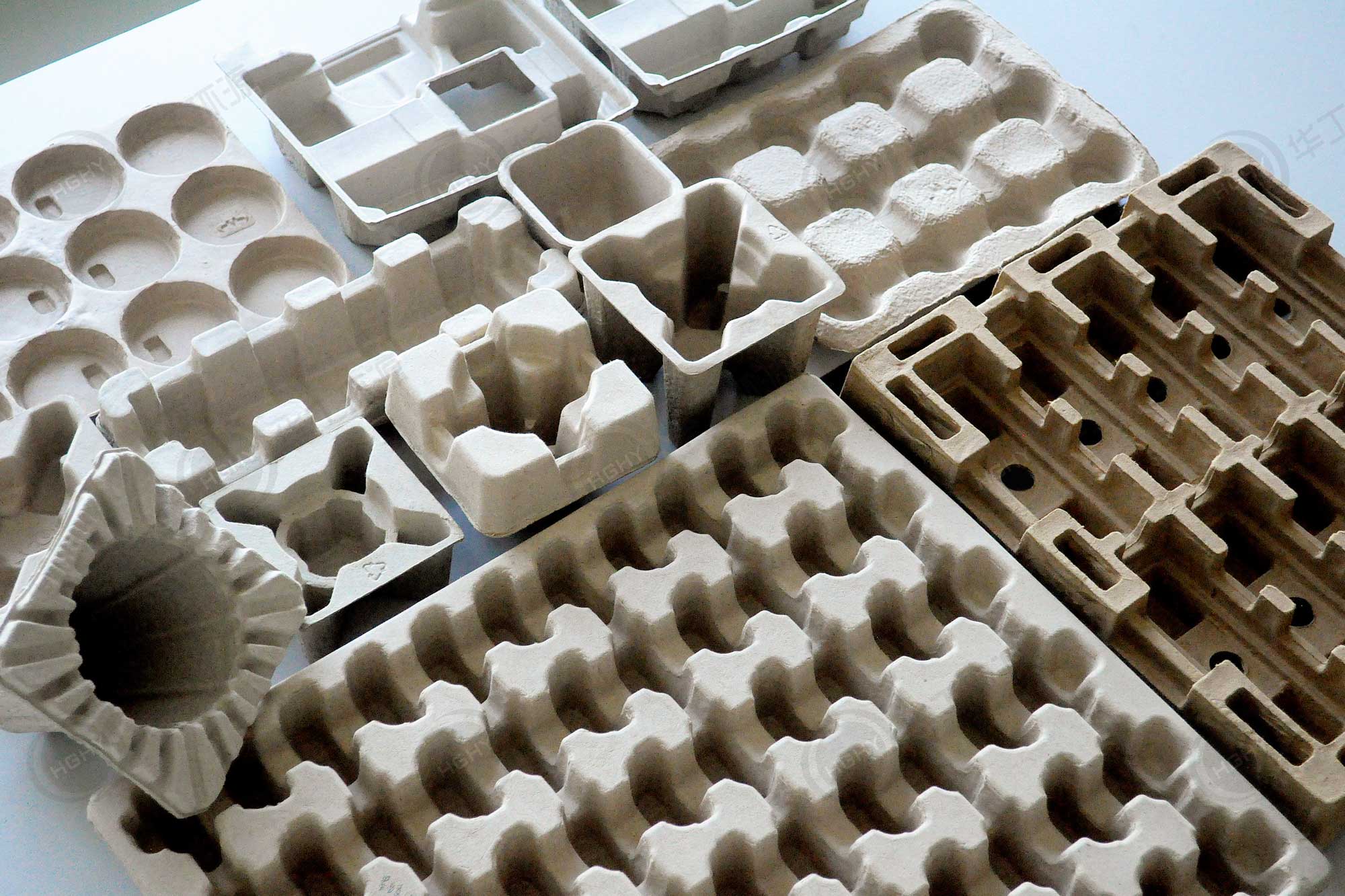

Pulp molded products are made of fully recyclable plant fiber pulp (wood, bamboo, sugarcane pulp, etc.) or recycled pulp from waste paper products as the base material, and are made of unique technology, which is widely used in food (medicine). ) pollution-free technology-based green products in the fields of product storage, electrical packaging, planting and raising seedlings, medical utensils, handicraft base blanks and fragile liner packaging.

1 Prospects and unique performance benefits

As an emerging green and environmentally friendly product, pulp molded products have wide application prospects, not only in catering, food, electronics, electrical appliances, computers, mechanical parts, industrial instruments, but also in handicraft glass, ceramics, toys, medicine, decoration In all walks of life, its application value has been more and more fully demonstrated.

The biggest highlight is that it is derived from natural fibers, returning to nature without polluting the environment at all, becoming a natural and organic part. It truly comes from nature, returns to nature, does not pollute the environment throughout its life cycle, fully conforms to the concept of environmental protection, and contributes to lucid waters and lush mountains that are invaluable assets.

According to the usage scenarios of pulp molded products, it can be divided into four major uses: agricultural packaging, food packaging, industrial packaging and medical product packaging.

The technology is simple and practical, the production process is basically pollution-free, and meets the requirements of clean production.

Wide source of raw materials, low cost. It mainly uses waste paper or annual herb fiber pulp.

The product has high strength, good plasticity and cushioning performance.

Light weight, low recycling cost, and reusable.

From production use to waste disposal, no pollution to the environment,

In the production process, the consumption of water is small, no waste water is discharged, and environmental pollution is reduced.

It has good air permeability and has unique benefits for the packaging of fresh products.

Pulp moldings have good water absorption, hydrophobicity and thermal insulation.

If special additives are added in the production process, it has special properties such as waterproof, oil-proof and high temperature resistance.

Fully degradable in natural environment.

2 Products and Applications

With the improvement of pulp molding technology, it has also begun to be used in high-end electronic products, cosmetics, luxury goods and other fields, and there are stricter requirements on the appearance and size of products, that is, high-end pulp molding packaging, the goal of such paper plastics It is an alternative to blister and injection packaging.

3 Pulp molding process

The pulping process of pulp molding (plant fiber molding) products is to use virgin cardboard, waste paper, carton, etc. as raw materials, through pulping, refining and other processes, to make paper into fibers, which are suspended in water to form pulp liquid. Then vacuum is used to adsorb the pulp liquid in a special mold to form a wet blank, and the finished product is formed through hot pressing drying, trimming and other processes.

HGHY Automatic Rotary Egg Tray Production Line

HGHY Pulp Molded Tableware Production Line

HGHY Pulp Molded Tableware Production Line

4 Summary and Outlook

With the improvement of people's living standards and the enhancement of environmental protection awareness, as well as the continuous improvement and promotion of pulp molding product technology, the application scenarios of pulp molding products are becoming more and more extensive. It is precisely because pulp molding (plant fiber molding) products have sufficient raw material sources, pollution-free production and use process, wide application range, low cost, light weight, high strength, plasticity, cushioning, interchangeability, and spring loading performance. Good, it can be used repeatedly and recycled, so it has strong vitality and broad application prospects.

Play a greater role in global environmental protection and plastic ban, and its economic value and alternative status have been recognized by the international community.